Reducer (Heavy Duty / Light Duty)

Reducer (Heavy Duty / Light Duty)

In Line (Heavy Duty / Light Duty) Manufacturer & Supplier – SWASTIK

If you are searching for a trusted In Line (Heavy Duty / Light Duty) Manufacturer and In Line (Heavy Duty / Light Duty) Supplier in India, SWASTIK stands as one of the most reliable and advanced producers in the industry. With years of engineering experience, precision-driven production methods, and a strong commitment to quality, we deliver robust and efficient In Line systems designed for long-term performance across multiple industrial applications. Our products are trusted across Kolkata, Andhra Pradesh, Telangana, Kerala, Uttar Pradesh, Madhya Pradesh, Tamil Nadu, Karnataka, Hyderabad, Odisha, Jharkhand, Bihar, Chhattisgarh, Assam, Indore, and Gujarat.

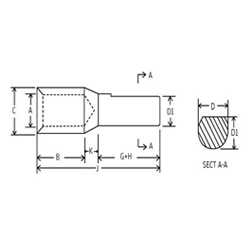

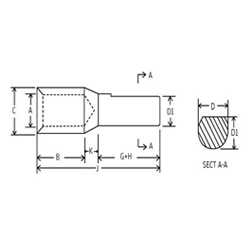

| Area mm2 | Cable Size | A | C | D | D-1 | B | K | G+H | J | Swastik Cat No. |

| 2.5 | 3/1.06 | 2.5 | 4.7 | 4.5 | 4.0 | 6 | 4 | 10 | 20 | SCR- 01 |

| 2.5 | 3/1.06 | 2.5 | 4.7 | 3.8 | 3.3 | 6 | 4 | 10 | 20 | SCR- 07 |

| 4 | 7/0.85 | 2.8 | 4.7 | 4.5 | 4.0 | 6 | 4 | 10 | 20 | SCR- 15 |

| 4 | 7/0.85 | 2.8 | 4.7 | 3.8 | 3.3 | 6 | 4 | 10 | 20 | SCR- 16 |

| 6 | 1/2.8 | 3.1 | 4.7 | 4.5 | 4.0 | 6 | 4 | 10 | 20 | SCR- 17 |

| 6 | 1/2.8 | 3.1 | 4.7 | 3.8 | 3.3 | 6 | 4 | 10 | 20 | SCR- 18 |

| 10 | 1/3.55 | 3.8 | 5.5 | 4.5 | 4.0 | 9 | 4 | 10 | 23 | SCR- 19 |

| 10 | 1/3.55 | 3.8 | 5.5 | 3.8 | 3.3 | 9 | 4 | 10 | 23 | SCR- 20 |

| 10 | 7/1.4 | 4.4 | 6.2 | 4.5 | 5.5 | 9 | 4 | 10 | 23 | SCR- 21 |

| 10 | 7/1.4 | 4.4 | 6.2 | 3.8 | 5.5 | 9 | 4 | 10 | 23 | SCR- 22 |

| 16 | 7/1.7 | 5.3 | 7.1 | 6.0 | 3.3 | 12 | 5 | 15 | 32 | SCR- 23 |

| 16 | 7/1.7 | 5.3 | 7.1 | 6.0 | 5.5 | 12 | 5 | 20 | 37 | SCR- 24 |

| 16 | 7/2.24 | 5.3 | 7.1 | 3.8 | 3.3 | 12 | 5 | 13 | 30 | SCR- 02 |

| 25 | 7/2.24 | 7.0 | 9.0 | 6.0 | 5.5 | 12 | 5 | 15 | 32 | SCR- 25 |

| 25 | 7/2.5 | 7.0 | 9.0 | 7.5 | 6.5 | 12 | 5 | 20 | 37 | SCR- 03 |

| 35 | 19/1.8 | 8.0 | 10.0 | 7.5 | 6.5 | 12 | 5 | 20 | 37 | SCR- 04 |

| 50 | 19/1.8 | 9.2 | 11.2 | 7.5 | 6.5 | 16 | 5 | 20 | 41 | SCR- 26 |

| 50 | 19/1.24 | 10.4 | 14.0 | 14 | 13 | 18 | 7 | 24 | 49 | SCR- 05 |

| 70 | 192.24 | 11.5 | 13.8 | 7.5 | 6.5 | 18 | 5 | 20 | 43 | SCR- 27 |

| 70 | 19/2.24 | 11.5 | 13.8 | 11.5 | 10.5 | 18 | 5 | 25 | 48 | SCR- 06 |

| 70 | 19/2.24 | 11.5 | 13.8 | 11.5 | 10.5 | 18 | 5 | 32 | 55 | SCR- 28 |

| 95 | 19/2.5 | 12.8 | 15.6 | 11.5 | 10.5 | 20 | 6 | 25 | 51 | SCR- 29 |

| 95 | 19/2.5 | 12.8 | 15.6 | 11.6 | 14.0 | 20 | 6 | 27 | 53 | SCR- 08 |

| 95 | 19/2.5 | 12.8 | 15.6 | 7.5 | 6.5 | 20 | 6 | 22 | 48 | SCR- 31 |

| 95 | 19/2.5 | 12.8 | 15.6 | 12.8 | 11.8 | 20 | 6 | 32 | 58 | SCR- 32 |

| 120 | 37/2.06 | 14.8 | 17.8 | 11.5 | 10.5 | 22 | 6 | 25 | 53 | SCR- 33 |

| 120 | 37/2.06 | 14.8 | 17.8 | 7.5 | 6.5 | 22 | 6 | 22 | 50 | SCR- 34 |

| 120 | 37/2.06 | 14.8 | 17.8 | 11.5 | 10.5 | 22 | 6 | 32 | 60 | SCR- 35 |

| 120 | 37/2.06 | 14.8 | 17.8 | 15.6 | 14 | 22 | 6 | 25 | 53 | SCR- 36 |

| 150 | 37/2.24 | 16.0 | 19.6 | 15.6 | 14 | 26 | 6 | 32 | 64 | SCR- 10 |

| 150 | 37/2.24 | 16.0 | 19.6 | 11.5 | 10.5 | 26 | 6 | 32 | 64 | SCR- 37 |

| 185 | 37/2.5 | 18 | 22 | 15.6 | 14 | 32 | 6 | 32 | 70 | SCR- 30 |

| 185 | 37/2.5 | 18 | 22 | 11.5 | 10.5 | 32 | 6 | 32 | 70 | SCR- 38 |

| 225 | 37/2.8 | 20 | 26 | 15.6 | 14 | 38 | 8 | 32 | 78 | SCR- 39 |

| 225 | 37/2.8 | 20 | 36 | 21 | 18 | 38 | 8 | 42 | 88 | SCR- 46 |

| 225 | 37/2.8 | 20 | 26 | 16 | 15 | 38 | 8 | 42 | 88 | SCR- 42 |

| 240 | 61/2.24 | 22 | 26 | 16 | 15 | 38 | 8 | 42 | 88 | SCR- 44 |

| 240 | 61/2.24 | 22 | 26 | 15.6 | 14 | 38 | 8 | 32 | 78 | SCR- 43 |

| 300 | 61/2.5 | 24 | 28.7 | 16 | 15 | 42 | 8 | 42 | 92 | SCR- 45 |

| 300 | 61/2.5 | 24 | 28.7 | 15.6 | 14 | 42 | 8 | 32 | 82 | SCR- 47 |

| 400 | 61/3.0 | 27 | 33.2 | 15.6 | 14 | 46 | 12 | 32 | 90 | SCR- 101 |

MATERIAL : COPPER : 1897

FINISH : ELECTRO TINNED

Tolerance = ± 5%

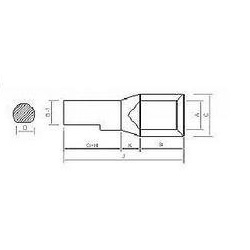

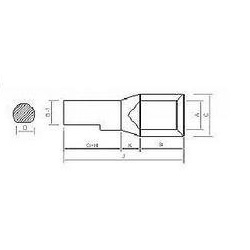

SWASTIK COPPER REDUCER TYPE TERMINAL ENDS FOR SOLDERING LESS CRIMPING TO ALUMINIUM CONDUCTORS SUITABLES FOR KWH METER

| DIMENSIONS(mm) | ||||||||||||

| Area mm2 | Cable size | A | C | D | D-1 | B | K | G+H | J | Swastik CAT NO. | ||

| 1.5 | 1/1.4 | 1.8 | 4.7 | 4.7 | 2.7 | 8 | – | 17 | 23 | SSR-36 | ||

| 2.5 | 3/1.06 | 2.5 | 4.7 | 4.7 | 2.7 | 8 | – | 17 | 23 | SSR-37 | ||

| 4 | 7/0.85 | 2.8 | 4.7 | 4.7 | 2.7 | 8 | – | 17 | 23 | SSR-38 | ||

| 6 | 1/2.8 | 3.1 | 4.7 | 4.7 | 2.7 | 8 | – | 17 | 23 | SSR-39 | ||

| 10 | 1/3.55 | 3.8 | 5.5 | 5.0 | 4.5 | 11 | 2 | 17 | 30 | SSR-40 | ||

| 10 | 7/1.4 | 4.4 | 6.2 | 5.0 | 4.5 | 11 | 2 | 17 | 30 | SSR-41 | ||

| 16 | 7/1.7 | 5.3 | 7.1 | 5 | 4.5 | 14 | 3 | 17 | 34 | SSR-42 | ||

| 25 | 7/2.24 | 7.0 | 9.0 | 5.0 | 4.5 | 14 | 3 | 17 | 34 | SSR-43 | ||

| 35 | 7/2.5 | 8.0 | 10.0 | 5.0 | 4.5 | 14 | 3 | 17 | 34 | SSR-44 | ||

| 50 | 19/1.8 | 9.2 | 11.2 | 7.5 | 6.5 | 18 | 3 | 20 | 41 | SSR-45 | ||

| 70 | 19/2.24 | 11.5 | 13.8 | 7.5 | 6.5 | 20 | 3 | 20 | 43 | SSR-46 | ||

MATERIAL : COPPER : 1897

FINISH : ELECTRO TINNED

Tolerance = ± 5%

SWASTIK BRASS REDUCER TYPE SOLDERING TERMINALS FOR ALUMIUM CONDUCTORS SUITABLE ON THE BASIS OF CURRENT AND CROSS SECTION APPLICATION :SWITCH FUSE UNITS,ETC.

| DIMENSIONS(mm) | ||||||||||||

| Amps mm2 | Cable size | E | A | C | D | F | B | K | H | G | J | Swastik cat no. |

| 15* | 7/1.4 | 1.6 | 5.2 | 8.0 | 4.5 | 4.0 | 9 | 5 | 13 | – | 27 | SBR 1440 |

| 30* | 7/2.24 | 8.0 | 11.2 | 6.4 | 5.5 | 6.4 | 11 | 7 | 17 | – | 35 | 1441 |

| 60* | 19/1.8 | 3.2 | 11.1 | 15.9 | 9.0 | 7.0 | 18 | 10 | 22 | 3 | 50 | 1442 |

| 100* | 19/2.24 | 3.2 | 14.2 | 19.0 | 12.7 | 9.5 | 22 | 10 | 25 | 3 | 57 | 1443 |

| 150* | 37/2.06 | 3.2 | 17.4 | 22.2 | 14.2 | 11.0 | 25 | 11 | 34 | 3 | 70 | 1444 |

| 200* | 37/2.5 | 3.2 | 20.6 | 25.4 | 16.7 | 13.5 | 25 | 11 | 34 | 3 | 70 | 1445 |

| 300* | 61/2.24 | 3.2 | 23.8 | 28.6 | 17.5 | 15.9 | 27 | 8 | 38 | – | 73 | 1446 |

| 50** | 19/1.8 | 3.2 | 11.1 | 15.9 | 7.0 | 5.5 | 19 | 6 | 27 | – | 52 | 1447 |

| 70** | 19/2.24 | 3.2 | 14.2 | 19.0 | 9.5 | 7.0 | 22 | 6 | 22 | – | 50 | 1448 |

| 150** | 37/2.24 | 3.2 | 20.6 | 25.4 | 15.8 | 7.0 | 28 | 8 | 22 | – | 58 | 1449 |

| 150** | 37/2.24 | 3.2 | 20.6 | 25.4 | 15.8 | 11.1 | 25 | 6 | 32 | – | 63 | 1450 |

| 300** | 61/2.5 | 3.2 | 26.2 | 31.8 | 22.0 | 11.1 | 28 | 8 | 22 | – | 58 | 1451 |

| 300** | 61/2.5 | 3.2 | 26.2 | 31.8 | 22.0 | 15.9 | 25 | 6 | 35 | – | 66 | 1452 |

| 300** | 61/2.5 | 3.2 | 26.2 | 31.8 | 22.0 | 15.9 | 25 | 6 | 38 | – | 69 | 1703 |

| 400** | 61/3.0 | 3.2 | 31.8 | 36.5 | 23.8 | 19.0 | 28 | 6 | 38 | – | 72 | 1704 |

MATERIAL : COPPER : 1897

FINISH : ELECTRO TINNED

Tolerance = ± 5%

Industries We Serve

Our In Line (Heavy Duty / Light Duty) systems are used in:

- Manufacturing Industries

- Packaging Industries

- Warehouses & Logistics

- Food & Beverage Units

- Steel & Heavy Engineering

- E-Commerce Hubs

- Retail Distribution Centers

- Pharmaceutical & Chemical Industries

- Automobile & Assembly Units

Wherever efficient product movement or alignment is needed, SWASTIK offers the perfect solution.

Service Locations – We Deliver Across India

SWASTIK supplies high-performance In Line systems to a wide range of locations including:

Kolkata, Andhra Pradesh, Telangana, Kerala, Uttar Pradesh, Madhya Pradesh, Tamil Nadu, Karnataka, Hyderabad, Odisha, Jharkhand, Bihar, Chhattisgarh, Assam, Indore, and Gujarat.

No matter your location, we ensure professional support, fast communication, and timely delivery.

Benefits of Choosing SWASTIK In Line Systems

- 1. Increased Productivity

Our units are designed for continuous operations, helping industries achieve faster workflow and reduced downtime.

- 2. Low Maintenance & Long Life

High-grade materials and precise engineering ensure minimal maintenance, making our systems cost-effective.

- 3. Smooth and Reliable Operation

Whether heavy or light duty, each system runs smoothly, reducing manual effort and operational delays.

- 4. Custom-Made for Unique Industrial Needs

Different industries need different inline designs. SWASTIK offers tailor-made inline systems to match your exact requirements.

- 5. Best Pricing in the Market

As a direct manufacturer in India, we offer competitive and transparent pricing without compromising on quality.

SWASTIK Quality Assurance

Every In Line system undergoes:

- Load testing

- Structural inspection

- Durability checks

- Movement smoothness testing

- Final quality approval

Our strict testing process ensures that our customers receive products that perform flawlessly for years.

Applications of In Line (Heavy Duty / Light Duty)

- Material movement in factories

- Conveyor alignment support

- Sorting and packaging units

- Food processing plants

- Warehouse handling systems

- Industrial conveyor lines

- Loading and unloading support units

- Assembly line workstations

From small production units to large industrial factories, SWASTIK’s In Line systems enhance efficiency wherever installed.

Choose SWASTIK – The Most Reliable In Line Manufacturer & Supplier

At SWASTIK, we believe in delivering engineering excellence with every product. Our commitment to quality, reliability, and customer satisfaction has made us a recognized name across India. Whether you need Heavy Duty In Line systems or Light Duty In Line solutions, our products deliver unmatched performance.

We serve businesses of all sizes and ensure seamless installation support, technical guidance, and after-sales service.