DOUBLE Compression Flam Proof Gland

DOUBLE Compression Flam Proof Gland

Technical Specification

| Material : | Brass (IS-319) Standard, (Al. / S.S. / M.S. also available) |

| Plating : | Nickle Plated Standard, (Chrome also available) |

| Entry Threads : | BSC Standard (PG / Metric / NPT / BSP / also available) |

| Sealing Rubber Ring : | Neoprene |

| Gland Standard : | BS 6121, IS/IEC 60079-0:2004 |

| Ingress Protection : | IP 66 as per IS/IEC 60529:2001 |

| Series | SCF |

| Make | Swastik |

Application:

Flame Proof Double Compression Glands Are Generally Used In Flammable Gas / Vapors Area (For Gas Group I, IIA & IIB) As Well As In Normal Climatic Conditions Also Which Are Weather Proof, Water Proof And Dust Proof (IP-66) Which Can Be Used In Hazardous Climatic Condition. Also When Protected By PVC Shrouds It Can Be Used In Corrosive Atmosphere.

These Glands Are Available In Different Sizes And Are Suitable For All Cables Upto 1000 Sq. Mm. And Control Cables Upto 61 Cores.

Accessories:

PVC Shroud, Earth Tag, Stopping Plug, Reducer, Adaptor, Etc. Are Available With Specified Dimensions In Accordance To The Gland Separately.

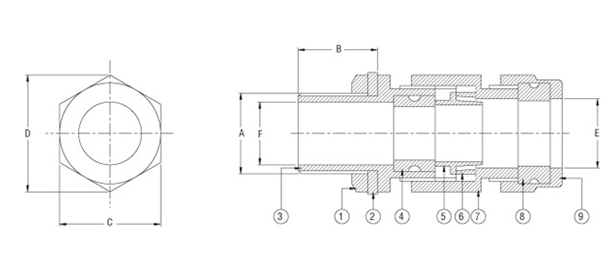

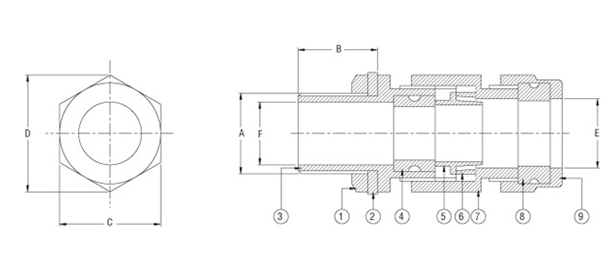

Fitting Sequence:

(a) Insert Part No. 9, 8 & 7 respectively on the Outer Sheath of the cable before exposing the Armour.

(b) After removing Outer Sheath of the cable, Insert Part No. 6 over the Exposed Armour.

(c) Size Armour length, Lift Armour & Insert Part No. 5 under the Armour, Taper Part Facing Inward Side, Squeeze Part No. 5 by pushing Part No. 6 towards it.

(d) Insert Part No. 4 & 3 on Inner Sheath, than tight Part No. 3 with Part No. 7 & Tight Part No. 9 with Part No. 7.

(e) Finally apply the full fitted Gland in the Enclosure with the entry thread provided, if the Enclosure does not have threaded entry than tight the Gland with

| Suitable Cable Overall Dia | SBW Code | A Nipple Entry | B Length | C (A/F) | D (A/C) | E Dia. | F Dia | |

| From | To | SCF Series | Inches | mm | mm | mm | Ø mm | Ø mm |

| 6.0 | 12.0 | SCF 01SS | 3/4″ | 25.0 | 21.0 | 24.0 | 13.0 | 14.5 |

| 12.0 | 16.5 | SCF 01S | 3/4″ | 25.0 | 25.0 | 29.0 | 18.0 | 14.5 |

| 16.5 | 18.5 | SCF 01 | 3/4″ | 25.0 | 27.5 | 31.5 | 19.0 | 14.5 |

| 16.5 | 18.5 | SCF 01A | 1″ | 25.0 | 27.5 | 31.5 | 19.0 | 14.5 |

| 18.5 | 20.0 | SCF 02 | 1″ | 25.0 | 30.0 | 34.5 | 21.0 | 18.0 |

| 18.5 | 20.0 | SCF 02A | 3/4″ | 25.0 | 30.0 | 34.5 | 21.0 | 14.5 |

| 20.0 | 23.0 | SCF 03 | 1″ | 25.0 | 31.5 | 36.0 | 23.5 | 19.0 |

| 23.0 | 26.0 | SCF 04 | 1″ | 25.0 | 36.0 | 41.5 | 27.0 | 20.5 |

| 23.0 | 26.0 | SCF 04A | 1 1/4″ | 25.0 | 36.0 | 41.5 | 27.0 | 22.0 |

| 26.0 | 30.0 | SCF 05 | 1 1/4″ | 25.0 | 41.0 | 47.0 | 31.0 | 25.5 |

| 26.0 | 30.0 | SCF 05A | 1 1/2″ | 25.0 | 41.0 | 47.0 | 31.0 | 27.0 |

| 30.0 | 33.0 | SCF 06 | 1 1/2″ | 25.0 | 47.0 | 54.0 | 34.5 | 31.0 |

| 30.0 | 33.0 | SCF 06A | 1 1/4″ | 25.0 | 47.0 | 54.0 | 34.5 | 27.0 |

| 33.0 | 37.0 | SCF 07 | 1 1/2″ | 25.0 | 50.0 | 57.0 | 38.0 | 32.0 |

| 37.0 | 41.0 | SCF 08 | 2″ | 25.0 | 56.0 | 64.0 | 42.5 | 38.5 |

| 41.0 | 46.0 | SCF 09 | 2″ | 25.0 | 59.0 | 67.0 | 47.0 | 40.0 |

| 46.0 | 52.0 | SCF 010 | 2″ | 25.0 | 67.0 | 77.0 | 53.0 | 44.0 |

| 46.0 | 52.0 | SCF 010A | 2 1/2″ | 25.0 | 67.0 | 77.0 | 53.0 | 48.0 |

| 52.0 | 54.0 | SCF 011S | 2 1/2″ | 25.0 | 74.0 | 85.0 | 57.0 | 51.0 |

| 54.0 | 61.0 | SCF 011 | 2 1/2″ | 25.0 | 80.0 | 92.0 | 62.0 | 56.5 |

| 61.0 | 66.0 | SCF 012 | 3″ | 25.0 | 85.0 | 98.0 | 68.0 | 64.0 |

| 66.0 | 72.0 | SCF 013A | 3″ | 25.0 | 90.0 | 103.0 | 73.0 | 67.0 |

| 72.0 | 78.0 | SCF 013 | 3 1/4″ | 25.0 | 99.0 | 113.0 | 80.0 | 74.0 |

| 78.0 | 84.0 | SCF 014 | 3 1/2″ | 25.0 | 105.0 | 121.0 | 85.0 | 78.0 |

| 84.0 | 94.0 | SCF 015 | 4″ | 25.0 | 114.0 | 132.0 | 98.0 | 90.5 |

| 94.0 | 104.0 | SCF 016 | 4 1/2″ | 25.0 | 130.0 | 149.0 | 106.0 | 101.0 |

Tolerance = ± 5%

Technical Specification

| Material : | Brass (IS-319) Standard, (Al. / S.S. / M.S. also available) |

| Plating : | Nickle Plated Standard, (Chrome also available) |

| Entry Threads : | BSC Standard (PG / Metric / NPT / BSP / also available) |

| Sealing Rubber Ring : | Neoprene |

| Gland Standard : | BS 6121, IS/IEC 60079-0:2004 |

| Standard Ref. | (a) As to general requirement IS:13346-2004 (b) As to flameproof construction IS/IEC 60079-1:2004 (c) As to weatherproof construction IP 66 as per IS/IEC 60529:2001 |

| Series | SCF CODE MAKE – Swastik |

Application:

Flame Proof Double Compression Glands Are Generally Used In Hydrogen Gas/Vapours Area (For Gas Group IIC) As Well As In Normal Climatic Conditions Also Which Are Weather Proof, Water Proof And Dust Proof (IP-66) Which Can Be Used In Hazardous Climatic Condition. Also When Protected By PVC Shrouds It Can Be Used In Corrosive Atmosphere.

These Glands Are Available In Different Sizes And Are Suitable For All Cables Upto 1000 Sq. Mm. And Control Cables Upto 61 Cores.

Accessories:

PVC Shroud, Earth Tag, Stopping Plug, Reducer, Adaptor, Etc. Are Available With Specified Dimensions In Accordance To The Gland Separately.

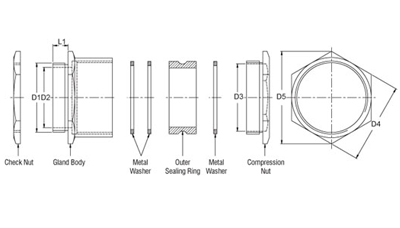

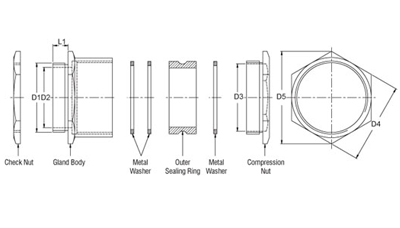

Fitting Sequence:

(a) Insert Part No. 10, 9, 8 & 7 respectively on the Outer Sheath of the cable before exposing the Armour.

(b) After removing Outer Sheath of the cable, Insert Part No. 6 over the Exposed Armour.

(c) Size Armour length, Lift Armour & Insert Part No. 5 under the Armour, Taper Part Facing Inward Side, Squeeze Part No. 5 by pushing Part No. 6 towards it.

(d) Insert Part No. 4 & 3 on Inner Sheath, than tight Part No. 3 with Part No. 7 & Tight Part No. 10 with Part No. 7.

(e) Finally apply the full fitted Gland in the Enclosure with the entry thread provided, if the Enclosure does not have thread than tight the Gland with the Part No. 1 provided.

| Suitable Cable Overall Dia | SCF CODE | D1 Nipple Entry | D2 Dia. | L1 Length | L2Length | C (A/F) | D (A/F) | C1 Dia. | |

| From | To | SCF CODE Series | Inches | Ø mm | mm | mm | mm | mm | Ø mm |

| 8.0 | 12.0 | SCF CODE 01SS | 3/4″ | 13.0 | 25.0 | 27.0 | 21.0 | 24.0 | 14.5 |

| 12.0 | 16.5 | SCF CODE 01S | 3/4″ | 18.0 | 25.0 | 27.0 | 25.0 | 29.0 | 14.5 |

| 16.5 | 18.5 | SCF CODE 01 | 3/4″ | 19.0 | 25.0 | 27.0 | 27.5 | 31.5 | 14.5 |

| 16.5 | 18.5 | SCF CODE 01A | 1″ | 19.0 | 25.0 | 27.0 | 27.5 | 31.5 | 14.5 |

| 18.5 | 20.0 | SCF CODE 02 | 1″ | 21.0 | 25.0 | 27.0 | 30.0 | 34.5 | 18.0 |

| 18.5 | 20.0 | SCF CODE 02A | 3/4″ | 21.0 | 25.0 | 27.0 | 30.0 | 34.5 | 14.5 |

| 20.0 | 23.0 | SCF CODE 03 | 1″ | 23.5 | 25.0 | 27.0 | 31.5 | 36.0 | 19.0 |

| 23.0 | 26.0 | SCF CODE 04 | 1″ | 27.0 | 25.0 | 27.0 | 36.0 | 41.5 | 20.5 |

| 23.0 | 26.0 | SCF CODE 04A | 1 1/4″ | 27.0 | 25.0 | 27.0 | 36.0 | 41.5 | 22.0 |

| 26.0 | 30.0 | SCF CODE 05 | 1 1/4″ | 31.0 | 25.0 | 27.0 | 41.0 | 47.0 | 25.5 |

| 26.0 | 30.0 | SCF CODE 05A | 1 1/2″ | 31.0 | 25.0 | 27.0 | 41.0 | 47.0 | 27.0 |

| 30.0 | 33.0 | SCF CODE 06 | 1 1/2″ | 34.5 | 25.0 | 27.0 | 47.0 | 54.0 | 31.0 |

| 30.0 | 33.0 | SCF CODE 06A | 1 1/4″ | 34.5 | 25.0 | 27.0 | 47.0 | 54.0 | 27.0 |

| 33.0 | 37.0 | SCF CODE 07 | 1 1/2″ | 38.0 | 25.0 | 27.0 | 50.0 | 57.0 | 32.0 |

| 37.0 | 41.0 | SCF CODE 08 | 2″ | 42.5 | 25.0 | 27.0 | 56.0 | 64.0 | 38.5 |

| 41.0 | 46.0 | SCF CODE 09 | 2″ | 47.0 | 25.0 | 27.0 | 59.0 | 67.0 | 40.0 |

| 46.0 | 52.0 | SCF CODE 010 | 2″ | 53.0 | 25.0 | 27.0 | 67.0 | 77.0 | 44.0 |

| 46.0 | 52.0 | SCF CODE 010A | 2 1/2″ | 53.0 | 25.0 | 27.0 | 67.0 | 77.0 | 48.0 |

| 52.0 | 54.0 | SCF CODE 011S | 2 1/2″ | 57.0 | 25.0 | 27.0 | 74.0 | 85.0 | 51.0 |

| 54.0 | 61.0 | SCF CODE 011 | 2 1/2″ | 62.0 | 25.0 | 27.0 | 80.0 | 92.0 | 56.5 |

| 61.0 | 66.0 | SCF CODE 012 | 3″ | 68.0 | 25.0 | 27.0 | 85.0 | 98.0 | 64.0 |

| 66.0 | 72.0 | SCF CODE 013A | 3″ | 73.0 | 25.0 | 27.0 | 90.0 | 103.0 | 67.0 |

| 72.0 | 78.0 | SCF CODE 013 | 3 1/4″ | 80.0 | 25.0 | 27.0 | 99.0 | 113.0 | 74.0 |

| 78.0 | 84.0 | SCF CODE 014 | 3 1/2″ | 85.0 | 25.0 | 27.0 | 105.0 | 121.0 | 78.0 |

| 84.0 | 94.0 | SCF CODE 015 | 4″ | 97.0 | 25.0 | 27.0 | 114.0 | 132.0 | 90.5 |

| 94.0 | 104.0 | SCF CODE 016 | 4 1/2″ | 106.0 | 25.0 | 27.0 | 130.0 | 149.0 | 101.0 |

Tolerance = ± 1%