Aluminum Tube Terminal (Light Duty)

Aluminum Tube Terminal (Light Duty)

SWASTIK ALUMINIUM TUBE TERMINAL ENDS

Alluminium Tube Terminal (Light Duty) Manufacturer & Supplier – SWASTIK

If you are searching for a reliable Alluminium Tube Terminal (Light Duty) Manufacturer and Supplier, SWASTIK stands as one of the most trusted names in India. We specialize in delivering precision-engineered aluminium tube terminals designed for light-duty electrical applications, ensuring excellent conductivity, durability, and performance. With a robust distribution network across Kolkata, Andhra, Telangana, Kerala, Uttar Pradesh, Madhya Pradesh, Tamil Nadu, Karnataka, Hyderabad, Odisha, Jharkhand, Bihar, Chhattisgarh, Assam, Indore, and Gujarat, SWASTIK has become a preferred choice for electrical contractors, industrial users, panel builders, and wholesalers.

With the help of good business ethics and international quality products like 40mm Aluminium Tube Terminals we have earned a respectful name in the domestic as well as in the global market. We deliver our products across the globe. Our fine quality products is what we boast of and our complete commitment towards our customers and backed by rich experience.

Established since 30 years , we are a trusted company in Aluminium Tube Terminals industry engaging almost thousands of clients each year . We are supplier of Aluminium Tube Terminals located in Mathura and its more products like . We are always available with quality-assured products.

aluminum is more affordable, copper is more efficient. Therefore, answer the question on which of the two should be used, isn’t easy. There is definitely the lure of low costs for electrical manufacturers. To be able to reap the advantages of both aluminum and copper, lately a whole lot of innovations have been taking place, largely in the form of copper coated aluminum Terminal lugs that reap the advantages of copper without incurring its cost. In fact, the aluminum Terminal lugs have a copper or nickel coating which in turn is covered with tin or silver. These coatings ensure that there isn’t formation of high-resistance aluminum oxide, which occurs even more in moist conditions. With the use of the coating the formation of aluminum oxide even in moist conditions is stalled.

The above innovations therefore make the use of aluminum that much safer. However, the common perception remains that copper Terminal lugs are much better to use than aluminum. Given the issues that arose with aluminum Terminal lugs earlier, this clearly is a mindset issue which will take time to overcome. This is not to say that aluminum bodied Terminal lugs do not have some failures. However, if they are used within their design parameters, statistically the probability of failure isn’t higher than that of any other lugs. Aluminum-bodied Terminal lugs are known to show signs of cracking during installation, which can be prevented using a torque wrench.

To sum up, while many people still trust only all Aluminium installations despite its price, as long as aluminum Terminal lugs have a copper or nickel flashing and tin or silver coating and the right torque wench is used during installation, there is no greater instance of statistical failure that has been noted. In choosing a lug due care must be taken to see what the main purpose of the cabling is, as also to see what kind of maintenance is required especially when the system is deployed in difficult conditions.

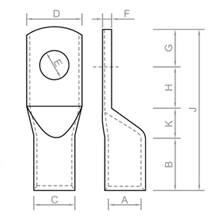

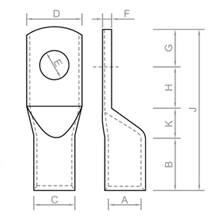

| Area mm2 | Cable Size | E | A | C | D | F | B | K | H | G | J | Swastik Cat No. |

| 2.5 | 1/1.8 | 3.2 | 2.0 | 5.5 | 6.6 | 3.5 | 7.0 | 3 | 4 | 4 | 18 | SAS 151 |

| 2.5 | 3/1.06 | 3.7 | 2.6 | 5.5 | 7.0 | 2.9 | 7.0 | 3 | 4 | 4 | 18 | SAS 309 |

| 4 | 7/0.85 | 4.2 | 2.9 | 5.5 | 7.2 | 2.6 | 7.0 | 3 | 4 | 4 | 18 | SAS 155 |

| 4 | 7/0.85 | 5.2 | 2.9 | 5.5 | 12.0 | 1.2 | 7.0 | 4 | 7 | 6 | 23 | SAS 317 |

| 6 | 7/1.12 | 5.2 | 3.5 | 5.5 | 8.0 | 2.0 | 7.0 | 4 | 7 | 6 | 24 | SAS 158 |

| 6 | 7/1.12 | 6.5 | 3.5 | 5.5 | 12.0 | 1.1 | 7.0 | 4 | 7 | 6 | 24 | SAS 313 |

| 10 | 1/3.54 | 4.4 | 3.8 | 6.2 | 8.4 | 2.4 | 7.0 | 4 | 9 | 8 | 28 | SAS 159 |

| 10 | 7/1.4 | 6.4 | 4.4 | 7.4 | 9.7 | 2.8 | 9.0 | 4 | 9 | 8 | 30 | SAS 214 |

| 10 | 7/1.4 | 8.2 | 4.4 | 7.4 | 9.7 | 2.8 | 9.0 | 4 | 9 | 8 | 30 | SAS 215 |

| 16 | 7/1.7 | 6.4 | 5.4 | 8.3 | 11.4 | 2.9 | 13.0 | 4 | 11 | 9 | 37 | SAS 252 |

| 16 | 7/1.7 | 8.2 | 5.4 | 8.3 | 11.4 | 2.9 | 13.0 | 4 | 11 | 9 | 37 | SAS 216 |

| 16 | 7/1.7 | 10.2 | 5.4 | 8.3 | 18.0 | 1.8 | 13.0 | 4 | 11 | 9 | 37 | SAS 217 |

| 25 | 7/2.24 | 6.4 | 7.0 | 10.0 | 14.0 | 3.0 | 16.0 | 7 | 12 | 9 | 44 | SAS 253 |

| 25 | 7/2.24 | 8.2 | 7.0 | 10.0 | 14.0 | 3.0 | 16.0 | 7 | 12 | 9 | 44 | SAS 218 |

| 25 | 7/2.24 | 10.2 | 7.0 | 10.0 | 20.0 | 1.7 | 16.0 | 7 | 11 | 10 | 44 | SAS 219 |

| 25 | 7/2.24 | 12.7 | 7.0 | 10.0 | 20.0 | 1.7 | 16.0 | 7 | 11 | 10 | 44 | SAS 220 |

| 35 | 7/2.5 | 6.4 | 8.0 | 10.8 | 15.0 | 2.8 | 18.0 | 7 | 11 | 11 | 47 | SAS 254 |

| 35 | 7/2.5 | 8.2 | 8.0 | 10.8 | 15.0 | 2.8 | 18.0 | 7 | 11 | 11 | 47 | SAS 221 |

| 35 | 7/2.5 | 10.2 | 8.0 | 10.8 | 20.0 | 2.1 | 18.0 | 7 | 11 | 11 | 47 | SAS 222 |

| 50 | 19/1.8 | 8.2 | 9.3 | 13.0 | 18.0 | 3.7 | 22.0 | 8 | 13 | 11 | 54 | SAS 255 |

| 50 | 19/1.8 | 10.2 | 9.3 | 13.0 | 23.0 | 2.8 | 22.0 | 8 | 13 | 11 | 54 | SAS 312 |

| 50 | 19/1.8 | 12.7 | 9.3 | 13.0 | 23.0 | 2.8 | 22.0 | 8 | 13 | 11 | 54 | SAS 224 |

| 70 | 19/2.24 | 8.2 | 11.6 | 16.0 | 22.0 | 4.4 | 26.0 | 8 | 13 | 13 | 60 | SAS 256 |

| 70 | 19/2.24 | 10.2 | 11.6 | 16.0 | 22.0 | 4.4 | 26.0 | 8 | 13 | 13 | 60 | SAS 225 |

| 70 | 19/2.24 | 12.7 | 11.6 | 16.0 | 22.0 | 4.4 | 26.0 | 8 | 13 | 13 | 60 | SAS 226 |

| 95 | 19/2.5 | 10.2 | 12.9 | 17.1 | 25.0 | 4.2 | 28.0 | 8 | 14 | 14 | 64 | SAS 227 |

| 95 | 19/2.5 | 12.7 | 12.9 | 17.1 | 25.0 | 4.2 | 28.0 | 8 | 14 | 14 | 64 | SAS 228 |

| 95 | 19/2.5 | 16.2 | 12.9 | 17.1 | 25.0 | 4.2 | 28.0 | 8 | 14 | 14 | 64 | SAS 229 |

| 120 | 37/2.06 | 10.2 | 14.8 | 19.6 | 28.0 | 4.8 | 32.0 | 11 | 15 | 15 | 73 | SAS 257 |

| 120 | 37/2.06 | 12.7 | 14.8 | 19.6 | 28.0 | 4.8 | 32.0 | 11 | 15 | 15 | 73 | SAS 230 |

| 120 | 37/2.06 | 16.2 | 14.8 | 19.6 | 28.0 | 4.8 | 32.0 | 11 | 15 | 15 | 73 | SAS 231 |

| 150 | 37/2.24 | 10.2 | 16.1 | 21.2 | 31.0 | 5.1 | 34.0 | 11 | 17 | 17 | 79 | SAS 258 |

| 150 | 37/2.24 | 12.7 | 16.1 | 21.2 | 31.0 | 5.1 | 34.0 | 11 | 17 | 17 | 79 | SAS 232 |

| 150 | 37/2.24 | 16.2 | 16.1 | 21.2 | 31.0 | 5.1 | 34.0 | 11 | 17 | 17 | 79 | SAS 233 |

| 185 | 37/2.5 | 10.2 | 18.0 | 23.7 | 34.0 | 5.7 | 36.0 | 12 | 18 | 18 | 84 | SAS 311 |

| 185 | 37/2.5 | 12.7 | 18.0 | 23.7 | 34.0 | 5.7 | 36.0 | 12 | 18 | 18 | 84 | SAS 234 |

| 185 | 37/2.8 | 16.2 | 18.0 | 23.7 | 34.0 | 5.7 | 36.0 | 12 | 18 | 18 | 84 | SAS 235 |

| 225 | 37/3.0 | 12.7 | 20.6 | 27.0 | 39.0 | 6.4 | 40.0 | 14 | 20 | 20 | 94 | SAS 320 |

| 240 | 37/3.0 | 12.7 | 22.0 | 28.0 | 40.0 | 6.0 | 44.0 | 14 | 22 | 22 | 102 | SAS 236 |

| 240 | 61/2.5 | 16.2 | 22.0 | 28.0 | 40.0 | 6.0 | 44.0 | 14 | 22 | 22 | 102 | SAS 237 |

| 300 | 61/2.5 | 16.2 | 24 | 31 | 45.7 | 7 | 47.0 | 14 | 27 | 27 | 115 | SAS 300 |

| 300 | 61/3.0 | 20.3 | 24 | 31 | 45.7 | 7 | 47.0 | 14 | 27 | 27 | 115 | SAS 259 |

| 400 | 61/3.0 | 20.3 | 28 | 36 | 51.0 | 8.0 | 56.0 | 13 | 31 | 30 | 130 | SAS 260 |

| 500 | 91/2.65 | 20.3 | 30 | 41 | 58.0 | 11 | 60.0 | 15 | 33 | 32 | 140 | SAS 296 |

| 630 | 91/3.0 | 20.3 | 35 | 46 | 66.0 | 11 | 69.0 | 16 | 35 | 34 | 154 | SAS 261 |

| 800 | 91/3.35 | 39 | 51 | 73.0 | 12 | 77.0 | 25 | 39 | 39 | 180 | SAS 318 | |

| 1000 | 91/3.75 | 43.5 | 57 | 81.0 | 13.5 | 100.0 | 30 | 45 | 45 | 220 | SAS 319 |

Tolerance = ± 5%